Hash rosin may be a relatively recent invention, but it comes from a much older method for extracting trichomes from cannabis — hashish. This weed product spread across Asia, Africa, and Europe, with the help of many pipes and edibles, for 1,000 years.

The evolution of hash to hash rosin

For the last 20 or 30 years, the best hash makers have been experimenting with new ways to create more potent, pure cannabis extracts.

Before 2015, weed lovers who wanted to toke on concentrates made without using solvents typically encountered ice water hash and dry sift, and occasionally charas, which is hand-rubbed from live plants. As these were often made in small batches, availability was limited.

Other smokers relied on concentrate made using solvent-based extraction methods — with butane hash oil (BHO) being the most popular — as it was more widely available.

The birth of hash rosin

In 2015, Phil "Soilgrown" Salazar was experimenting with pressing mid-grade hash. He wrapped the hash in parchment paper and squeezed it with a hair straightener to apply pressure. While he would've only expected his hash to melt, with extra accidental heat and pressure, he noticed oil beginning to escape from it.

The second time he did this, Salazar tried dabbing the rosin. He noticed the bright flavor, intense high, and lack of residual melted resin.

Once Salazar shared his discovery with the cannabis community, they demanded more of this new, more potent form of full-spectrum hash oil. While some solvent-free hash just wouldn't melt properly, rosin gave concentrate fans a clean, dabbable product with a better yield.

What is BHO?

BHO is any weed concentrate produced using butane solvent extraction. It's part of a wider group of substances made by using a volatile chemical to separate the essential elements from the plant material. Once this process is complete, the producer removes the solvent from the concentrate, usually through evaporation.

What are the alternatives to BHO?

Other concentrates are made by extracting the essential elements desirable elements of the plant without using a chemical solvent, which people are starting to call ‘SHO’ for solventless hash oil. There are several different ways to achieve this, and hash rosin is just one of them.

With growing consumer interest in extracts, chemists and amateurs alike experiment to see what they can get from the cannabis plant. You can make nearly all types of concentrate through either solvent-based or solventless extractions. Their names, such as shatter, wax, or oil, generally refer to their texture and consistency. For the most part, those terms are used to describe solvent-based extracts, and solventless concentrates are often described specifically by how they were made.

The solventless extraction method

So, how exactly do you extract cannabinoids without solvents? There are four main ways in addition to the traditional charas method:

Dry sift

"Kief" refers to the tiny crystal trichomes that form on the surfaces of buds. Most smokers who grind flower will notice this gold dust collect in their grinder. To separate this dry sift from the cannabis plant, the extractor agitates the buds across a series of fine mesh screens, letting the trichomes fall through.

Ice water hash (or bubble hash)

Ice water hash, or bubble hash, extraction requires soaking cannabis nugs in ice-cold water. The producer then agitates them, often using a machine. The trichomes separate and fall to the bottom, to be further sifted, dried out, and collected.

Pressed hash

To make pressed hash, you take kief (or sometimes bubble hash) and place it under heat and pressure, usually with a mechanical press. The result is a dense block of trichome resin. Note that this isn’t the same as rosin because it’s not done with enough heat and pressure to squeeze out any oil.

Hash rosin (the most recent)

After going through any of these hash making processes, producing hash rosin requires an extra ‘squashing’ step to create a highly pure, potent product.

What’s so special about hash rosin and why is it so expensive?

Hash rosin has a special place in the hearts of concentrate enthusiasts. As the popularity of solvent-free concentrates continues to rise, hash rosin is at the front of the trend, and often comes with the highest price tag.

Hash rosin is pure

Because hash rosin is first made without solvents or chemicals and then refined even further, many consider it the purest form of cannabis concentrate. Some users also think of it as a healthier option because they know that nothing except for water, heat, and pressure was used while the maker extracted it.

Others debate that the extract has generally higher potency and is, therefore, more effective. Although things like distillate can actually be more concentrated forms of cannabinoids than hash rosin, distillate only isolates a small set of compounds, whereas well-made hash rosin can contain the full set of cannabinoids, terpenes, and other compounds that was originally found in the flower.

Hash rosin is a solventless extract

Producers usually churn out solvent-based extracts at a higher volume, as they're easier to make (although the process does take longer). You might compare hash products made without solvents with a small craft brewery, as they have an artisanal feel and a higher price point. Sure, there's less end product, but makers filter them from a tip-top starting material, and they yield impressive results.

Because solvent strips the flower of its cannabinoids, it makes it easier to use lower-quality buds. With rosin, you expect to receive full-spectrum hash — with all of its elements intact — so the original bud has to meet a certain standard or the difference will be more noticeable.

Hash rosin is safer to make at home

When amateurs attempt to extract concentrates using solvents at home, they expose themselves to flammable and explosive chemicals. People really do sometimes cause sudden explosions in their basements and unfortunately, people have died doing so.

If a concentrate isn't properly filtered and purged of solvents, these poisonous chemicals will pass onto the person who consumes it. Hash rosin could be considered a better product because you can make it at home without the risk of causing serious harm to yourself, others, or someone’s property.

What is hash rosin made of?

Tiny crystals dot the surfaces of premium cannabis nugs. These are called trichomes, and they carry all the powerful cannabinoids and aromatic terpenes for the whole plant. Hash rosin is literally made from cannabinoid-filled oil that you extract from inside these trichome heads.

How hash rosin is made

All cannabis extraction methods that create concentrates remove the trichomes, those tiny beads on the nugs and ‘sugar leaf’, from the rest of the plant. This process makes sense when creating a high-potency product, as these trichomes hold all of the cannabinoids and terpene profile. You're simply discarding the plant matter.

Making flower rosin and hash rosin are slightly different processes, however.

Making rosin from flower

When creating flower rosin, you extract the trichomes using heat and pressure to squeeze them away from the buds and produce a resinous material. This is usually achieved using a hydraulic rosin press with heated metal plates.

You place the cannabis flower inside a mesh bag and tuck it between the two metal plates, then press them together tightly to provide the pressure needed. The bag acts as a filter by keeping the discarded plant material inside the bag. At the same time, the bag provides spaces for the oil from the trichome glands to seep out away from the plant. This oil is the rosin.

Another type of product is called ‘live’ rosin, which uses fresh flower instead of buds that have already been dried and cured. The rosin that comes from using fresh flower has a higher terpene content, so it carries a more aromatic smell and taste.

Making rosin from hash

You follow the same process to make hash rosin as when making flower rosin, with one difference. Instead of placing buds from the weed plant inside the bag, you use a solventless hash, either ice water hash or dry sift hash.

The hash is then placed in the same type of mesh bag before the heat and pressure is applied. The heads of the trichomes will rupture, and the oil stored within gets forced out, just like with flower rosin. Because there’s less waxy material in hash than flower, this creates a full-melt hash — one that won't leave any residue in the bowl once it's vaporized.

Hash rosin is often considered the highest quality rosin. That's because it has been through two refining processes, from both the extracted hash product and then the hash rosin extraction process, before becoming the end product. The rosin is more potent and there's less chance of any unvaporized material being left over after use.

You can easily make flower rosin or even hash rosin at home with a heated press or just a hair straightener, but before we get into that, let’s take a look at how the professionals do it in a licensed facility.

How shatter is made with BHO

Shatter is a type of cannabis concentrate with a shiny, glass-like appearance and a hard texture. It's similar to wax concentrate but has slightly different properties. Waxes are softer and easier to manipulate because the molecules in the extract were agitated while the concentrate was processed.

You can make shatter from cannabis flower, trim, or even kief. Producers create it using either solvent-based or solventless extraction methods. However, they usually opt to make it with hydrocarbon or butane solvents.

When you make shatter with solvents and a regulated process, it takes place within a closed-loop system that contains the fumes and stops them from entering the outside environment. Here are the steps professional shatter producers follow:

- You place the original plant matter into a column.

- The solvent is chilled, then you slowly push it over and through the plant material. It strips away the plant's desirable THC, CBD, and trichomes in the process.

- Collect and preserve the cannabinoid-rich oil that comes away from the plant.

- Remove the solvent from the solution through vaporization, evaporation, or another method. As solvent-based shatter is made under a low temperature and low pressure, it gains its glassy appearance.

- You can even further refine the shatter oil by other means, like a purge, which removes excess plant residue while inside a vacuum chamber.

How to make hash rosin with Pacific NW Roots

As one of the newer and rapidly evolving sectors in the cannabis industry, the hash rosin space has a shortage of true specialists. In many cases, hash rosin producers process material for other businesses, but you’ll also find a growing number of established flower producers that are producing their own hash rosin. Something you won’t see very often, however, is a dedicated hash business that produces and handles all of its own material from start to finish.

We recently found ourselves lucky enough to visit Pacific NW Roots in Washington State, where start-to-finish hash farming is exactly what they do! Not only is operator Ras Kaya Paul a master hash maker, he’s a well-respected hash plant breeder with a lineup that includes signatures like Koffee, Sofa King Kush, and Platinum Alien OG. Whether it comes from the raised beds of his indoor rooms or the hugelkultur beds of his outdoor greenhouse, he’s passionate about crafting quality products using all organic methods.

There’s a lot we could say about how streamlined the operation feels, especially for one that does everything from growing to packaging in-house. Amidst the whirlwind of talk about craft cannabis policies, It can be hard to figure out what it really takes for small businesses to succeed. The way we see it, it’s gonna take more eyes on operators like Pacific NW Roots to figure out how artisan producers can actually compete in the pressure cooker of legalization. We’ll explore the cultivation side of Pacific NW Roots another time, but for now, let’s get to the hash making!

We’ll start with a rundown of the logistics and then share some of Kaya’s tips for getting started.

Equipment

- Commercial ice machine (1000 lbs every 24 hours)

- Commercial walk-in freezer w/ sheet pan racks

- Four washing tubs

- Two home freeze dryers

- Small vacuum oven

- Hash rosin press with bags

Step 1: Harvest, prep, and storage

To be fair, step one is growing the weed, but once that’s done, this is where the plant’s journey into that gooey rosin goodness begins, and it’s where Ras Kaya Paul’s careful technique starts to pay off. First, whole plants are cut at the base and hung up so they can be “big leafed”, which means — you guessed it — the big leaves get stripped off. Then the plant is broken down into branches which get hung on a clothesline of sorts that hangs over a long table, with a row of trimmers on each side.

After that, Kaya tells me, “as it moves down, the big leaves come off, anything without sugar, and then the next trimmer will actually trim up the bud, and they are instructed to not cut the leaf or the plant matter but only the stems. This keeps the chlorophyll in the plant, keeps the plant intact so I get more spins out of it.” By spins he means washes, so in other words, careful handling allows for the better yield without compromising on quality. Kaya goes on, “So they break it up really small onto the racks, and we usually give it about 24, up to 48 hours to freeze. Once it’s frozen solid, we put it into bags and let it sit for another day or two with it open, and then you can close the bags. And then it's good to go until we wash it.”

A key takeaway is the importance of breaking down larger buds. Kaya explains, “You can see the buds are really broken down super far. These were huge buds, we knock em’ down nice and small and get all the surface area.”

Step 2: Washing the buds into hash

Once the flowers are broken down and properly frozen, they’re ready to be washed. For this step, the frozen buds are sloshed around by hand in tubs filled with ice and water as well as a mesh bag that holds back the green plant matter and allows the precious trichomes to drop through.

Afterwards, the trichrome-laden water is drained and Kaya says, “We'll scoop the hash out and sieve it, and then we basically sieve it out onto those racks,” as he points to a row of pan racks along the wall, “Then [we] set 'em in here to dry for like two weeks. And that's only the 6-star, 90 microns, first pull, maybe second, and then everything else gets batched together and thrown in freeze dryers.”

He’d later tell us how he used to dry hash on top of lamps or in his truck, but as we passed by the freeze dryers, we could tell they were something he was still excited to have in his facility. Entering the walk-in freezer, Kaya continues, “After we wash [and dry] it, it’s graded and it gets put into jars, and now it’s preserved. At this point I feel safe, I’m like, ‘Okay, I got it. My money’s secure’. And I can squash it if I want to. Now the 6-star, once it comes out of there and it's dried, we gram it out, and then it goes into these,” Kaya shows us a container, “and you can see it's like salt.”

Step 3: Squashing

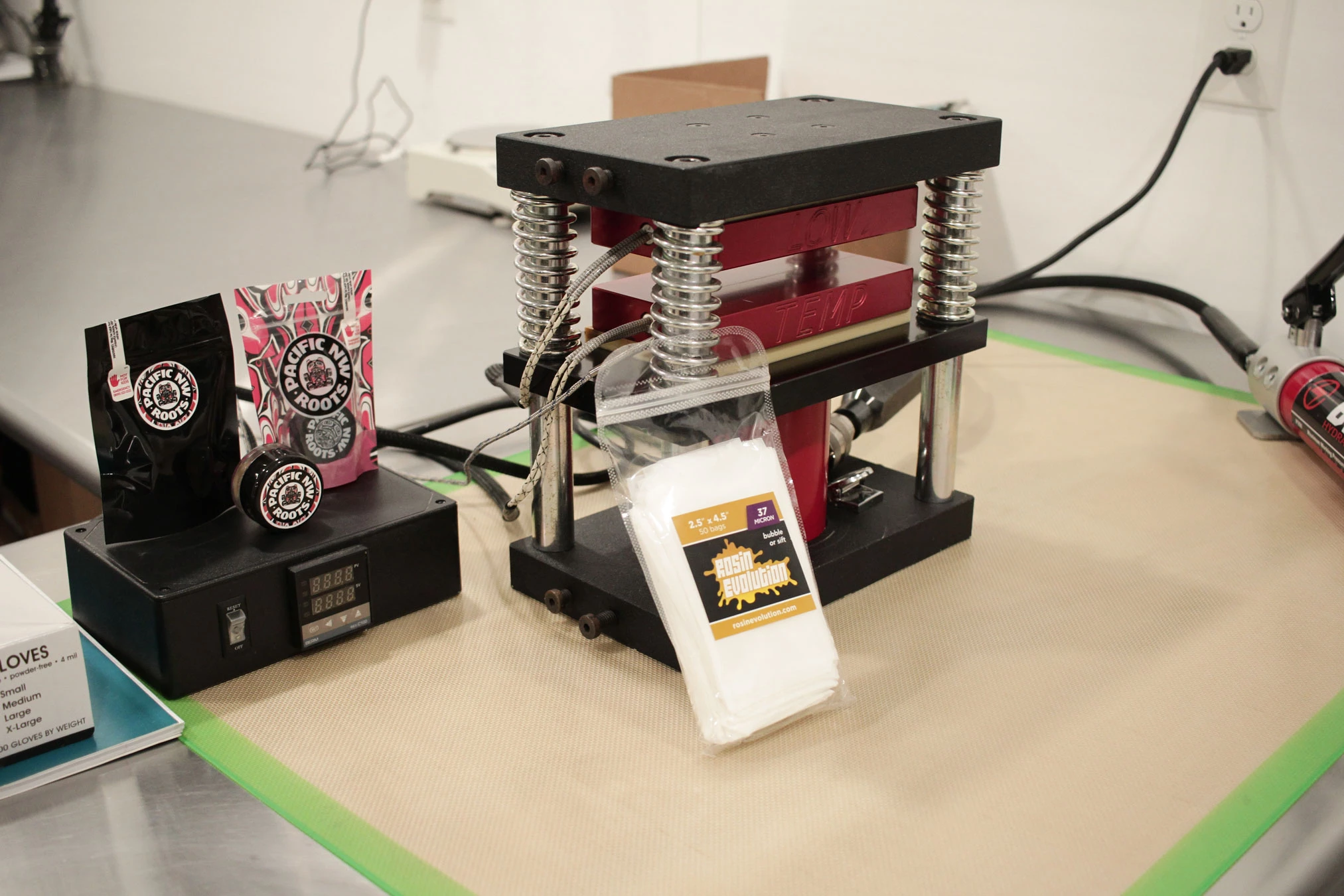

The final step is the one that turns the hash into rosin, and in some ways it’s the simplest part, especially considering how much work it’s taken to get this far. We were expecting to see something bigger, or somehow more commercial looking, but the small rosin press sitting on a table almost looked whimsical compared to the massive ice makers and other equipment we had just seen. As unassuming as appearances may be, without this tool, there’d be no rosin!

Even though you can purchase a similar product and use it in a spare closet, that doesn’t mean that Pacific NW Roots isn’t staying ahead of the curve when it comes to the details. First of all, the space is immaculately clean. All the efforts made to avoid contamination can be wasted if dust, hair, finger oils, or any other foreign material gets near the sticky goo that pours out from between the two heated plates. Kaya explains how they cover things like handles with nitrile gloves because touching any plastic or rubber material can leave small traces of residue on your gloves that would ruin the rosin if it came in contact.

Kaya also describes how things work when they take frozen resin, or hash, out of the freezer for pressing, saying, “The little bags in there, they bring ‘em out here … It’s a little mesh bag, they put like a half ounce in each one, and then they take the paper, and fold it up, origami style, [and it] slides in the gills. Generally we’re pressing at like 170 degrees, and then collecting the rosin, and then passing it back over, and then they immediately gram it up, [and] it goes on the shelves. Usually we’re running through whatever inventory we have during the week.”

And that’s basically it! The products retail for about $75-85 a gram and come in just under a dozen varieties including crowd favorites like GMO and Kush Mints, plus in-house specialties like Strawberry Yogurt and Hamma Hamma. Many of the samples we checked out had different looks and textures, but the aromas were stunning. If you haven’t had the pleasure of smelling a freshly harvested room, you can practically get the same experience by holding one of their jars under your nose. Remember, hash rosin is best when kept cold or frozen, but don’t forget to let the container warm up for 10-15 minutes before opening it or you’ll run into issues with condensation, which can destroy the delicate balance of terpenes in short order.

Before you go, here are a few more tidbits of knowledge from hash master Ras Kaya Paul.

More hash rosin tips with Pacific NW Roots

For the amateur rosin presser, there’s gonna be a learning curve and the easiest mistakes to avoid might not be the ones you expect. I asked Ras Kaya Paul of Pacific NW Roots where people tend to mess up, and he talked a lot about the freezing and drying process. Let’s go over some of what he said!

How do you freeze fresh buds?

Freezing fresh buds for hash washing doesn’t seem complicated, but when we ask Kaya which mistakes he sees most often, he starts at the beginning, when the plant is freshly harvested and ready for freezing. He tells us, “If you’re gonna do that, you’ve got to get it right into the freezer” but, more importantly, to be careful “if you take a hot plant and throw it in a plastic bag.” He says that most people will fill up a bag, close it, and throw it in the freezer and asks, “So, hot plants, cold, what happens? It’s gonna condensate. Now you get ice crystals all over your buds, it brings down your yield, and fucks up your stuff.”

In his facility, they use drying racks and walk-in freezers, but a home hash maker should give the plants time to cool off and bag them in a cold room, then leave the bag open in the freezer for a couple days before closing it.

Moving on, he says, “The other thing they fuck up is letting that defrost at any point. Once you defrost that herb once it’s frozen, you’re fucked. Your yield will go to two percent or less and it’s gonna taste like swamp ass.”

Kaya says the condensation and defrosting are probably the easiest mistakes to make, but what about handling the hash once it's washed from the buds?

How can I dry bubble hash? How long does it take?

When it comes to the hash washing process, Kaya’s primary advice is just as straightforward and, like harvesting and storage, it has more to do with handling than a special technique. He starts by telling us, “When drying stuff, don’t rush it” and continues, “I started drying hash on a lamp. We would scoop it out, and then chop it up as fine as we could. Chop it up on a plate, and set it on top of a light, and let it sit for up to 14 days. It can harden and get dry, and the inside would be gooey, and you had to get that inside gooiness a little bit dry, otherwise it would mold on you. So trying to get it as fine as you can, if you’re gonna air dry it.” For Kaya, his freeze dryers are a game changer, but for a home setup, he recommends a wine cooler or a small freezer saying, “As long as it’s cool, and it’s drying in there, you can dry hash in there.”

The golden rule of making hash rosin

Over the last half decade, the quality of rosin has come a long way. Thanks to improvements in machinery and the standard techniques, it’s a lot harder to find the tacky, burnt, flavorless rosin that flooded the market around 2015, and typical prices now range from $40-80 a gram on the west coast. There’s a lot of info out there regarding different techniques, but according to Kaya, there’s one golden rule to follow: “Good hash comes from good flowers, so start out by growing some good herbs.”

For that, Ras Kaya Paul has a small but close-knit team that he really trusts, including childhood friends and long-time business partners who know just how much attention to detail makes a difference. At the end of the tour, we talk about the greater context of farming, food, health, and his hopes of one day having on-site sales and consumption. The same sentiments are still shared by a lot of cannabis growers, but given the depth of experience and no frills game plan I saw in action, I can’t help but feel like Pacific NW Roots is gonna make it to the ‘other side’.

Live rosin vs. live resin: What's the difference?

If you've ever tripped up remembering whether to say "rosin" or "resin," you're not the only one. But the main difference between resin and rosin is simple. Rosin is a concentrate made without solvents, whereas ‘live resin’ generally refers to a solvent-based concentrate.

Producers make live resin from plant matter that's freshly harvested and flash-frozen. They usually then extract it with the help of a solvent and a closed-loop system. If they were to take the same starting material and press out the oil instead of a solvent extraction, it'd be live flower rosin.

Live hash rosin, on the other hand, uses a refined starting material so it requires an extra step. When hash makers take an existing solvent-free hash and press it further to create rosin, it can result in a higher potency extract without losing all the flavors and effects the material has to offer. That often means it has a higher THC content than solvent-extracted resin, with even better flavor and effects.

Where can I find high-quality hash rosin?

As people become more interested in the benefits of solventless hash, the market has grown considerably in recent years. That means more access to hash, but it also means the quality of this hash can vary a great deal.

Bubble hash has traditionally been graded using a ‘star’ system as well as several spot tests such as a melt test. If a person is shopping for hash on the street or from strangers, they may heat up a small sample to see how it melts and bubbles before agreeing on a price. Other times, you may find sellers using the star system.

This grading system is beginning to appear on product packaging. It will let you know how good the hash is, from 1 to 6 stars. Generally, the system is split into three tiers: 1 and 2-star hash is low grade, 3 and 4 stars is middle of the road, and 5 and 6-star hash is the best money can buy. Lower grades will contain more plant matter and burn with significant residue, while higher grades can be vaporized and leave behind little to no residue.

But where can you find the best hash rosin? Any renowned dispensary you walk into should carry at least one or two premium hash rosin products, but they generally aren’t graded in the same way as hash. That tends to make sense because pressing the hash rosin actually leaves behind most of the residues and contaminants in lower quality hash. So while you can find 6-star hash rosin on some menus, many experienced hash makers will choose NOT to press their 6-star because it’s already the highest quality, clean-dabbing material you can get.

Unfortunately, that means it can be hard to know the quality of starting material and just how well your hash rosin really captures the essence of that flower.

How much does hash rosin cost?

Without the star system, the price of hash rosin will depend mainly on two things: the cost of its starting material and the care taken during its processing. Other factors that might affect how much you pay for your hash rosin are whether you buy a larger amount and benefit from a discounted bulk price, and price variations between different states.

Generally speaking, however, trends have emerged that can allow us to estimate the price of hash rosin. The following prices represent established recreational markets (like Colorado and Washington) without limited licensing (hash rosin in places like Illinois will be extremely overpriced for its poor quality).

- $25: If you pay this price per gram, don't expect to receive a great quality product. We don’t recommend hash rosin in this price range.

- $40-$55: If you're prepared to shell out a little more for a gram, you may receive a good quality hash rosin product, but it might be from mixed strains and/or won’t capture the true flavor and effects of higher qualities.

- $60-80: In this price range, you can find high quality hash rosin which has the strain-specific aroma, flavor, and effects of fresh flowers. Expect to pay $80 for the best quality.

- $100+: The "6-star" hash rosin products on the market may cost $100 or more, and at this price, we tend to prefer going with the unpressed hash because, when done right, there’s no need to press 6-star.

Can I make hash rosin at home?

You can absolutely make your own hash rosin from the comfort of your own home. What's more, you can create products without solvents safely. As you're not using volatile substances, you don't need to worry about causing an explosion.

It may take some practice, but making your own hash rosin will give you a wonderfully fresh and flavorsome end product. You'll get a concentrate that successfully preserves the full spectrum of terpenes in your weed and delivers a clean high, too. That being said, if you aren’t growing the weed yourself, it’s probably won’t be very economical, but it’s still fun to experiment!

To make your own hash rosin, gather these tools first:

Cannabis concentrate (whichever form you have)

- Hair straightener

- Parchment paper (not wax paper)

- Mesh bag or nylon food-grade screens

- Dabber or another similar tool to scoop up the rosin

- Heat-resistant gloves (recommended)

- Container (if making more than two dabs)

Step 1: Break off a piece of concentrate that will fit inside two pieces of parchment paper and within the boundaries of the hair straightener.

Step 2: Place the concentrate inside the mesh bag.

Step 3: Set a low temperature on your hair straightener. Work your way up through trial and error as too much heat can burn the concentrate, producing dark, runny rosin.

Step 4: Place the bag between the two papers, leaving a couple of inches of extra paper on all sides to make sure the rosin doesn't spill onto the plates underneath.

Step 5: Press the paper firmly between the straightener, on a flat surface, for between four and 30 seconds (experiment to find the right timing for your set-up).

Step 6: Reposition the bag of original hash onto a new part on the paper if needed, and repeat the pressing process until no new rosin comes out.

Step 7: Use the dabber to collect your new hash rosin.

Step 8: Place the rosin in an airtight glass jar for long-term storage. Otherwise, you can leave it between the paper for a short while until you use it.

Best ways to smoke hash rosin

Even if you get yourself some exciting hash rosin, what are the best ways to smoke it?

To start with, make sure your hash rosin is full-melt. As a true hash rosin product has been refined into a concentrate twice, it should melt fully. You should never see any residue left behind when you heat it.

Dabbing: This traditionally involves heating a nail with a blow torch and melting concentrate onto it for its vapors to be inhaled through a tube.

This method can be fiddly and downright dangerous for the inexperienced user. However, an e-nail should allow you to dab your hash rosin equally well.

Vaping: Electronic dab pens contain a built-in heating element and a chamber but still let you select your own concentrate. They're much easier and discreet to use, allowing you to gently warm and vaporize your hash rosin.

Dab pens are ideal for hash rosin made from ice water/bubble hash, as you're able to fully appreciate the amazing aromas of the terpenes that have been carried through each production stage.

Smoking: You may prefer to simply crush, then pack a tiny amount of hash rosin into a bowl and smoke it up. Just place a fine-mesh screen over the mouth of your pipe's ignition chamber so you're not hit by dry hash in your mouth.

You can also sprinkle crumbs of hash rosin over a joint, blunt, or spliff. This will add a powerful extra hit to your smoking experience, so always prepare any flower/concentrate combos with caution.

Conclusion

Everyone has their own preferences when it comes to weed, but it's hard to dispute that hash rosin is a revolutionary way to capture the live essence of a plant in a consumable product. Its potency, flavor, and effects are hard to beat. The invention of hash rosin has also opened some exciting doors for producers. When it comes to competing on today’s market, hash rosin has the potential to make a huge difference. It might be the most economical way to produce connoisseur grade products from sustainably grown crops, giving craft producers value-added options that fetch top dollar.

Why not treat yourself to a new concentrate the next time you're at a dispensary, or try making your own hash rosin at home?